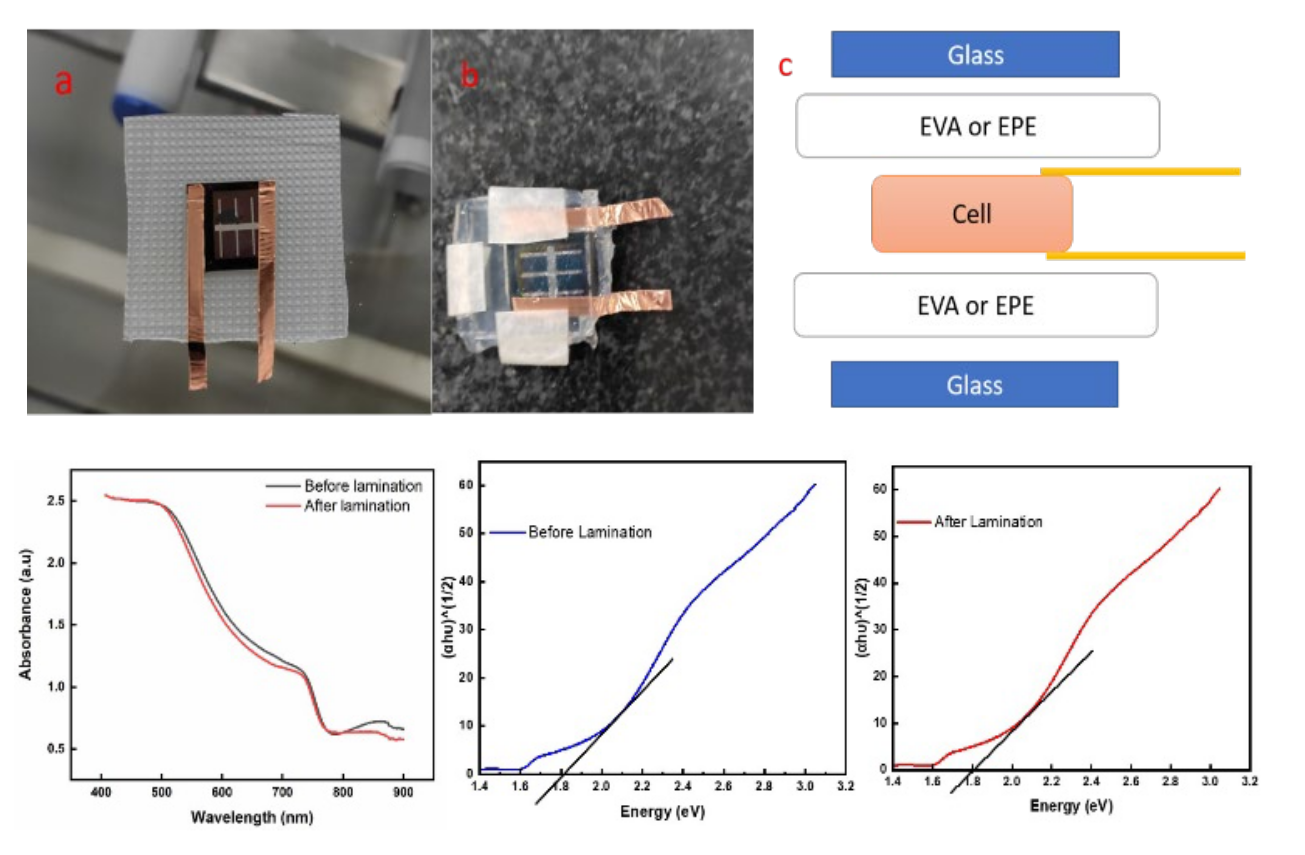

Si-Perovskite Tandem cells have high efficiency but the stability of these cells is dependent on the stability of perovskite solar cells which are vulnerable to moisture, oxygen, UV, and temperature. So, proper encapsulation is required to support perovskite solar cells (PSC). In this work, we have used the regular n-i-p architecture-based NIR transparent PSCs where the triple cation perovskite Cs0.05(MA0.17FA0.83)0.95Pb(I0.83Br0.17)3is used as the photo absorber. The perovskite cell is a composite of three layers on FTO glass SnO2 as Electron transport layer (ETL), Spiro MeOTAD, and ITO are used for electrode deposition. Ethylene-vinyl acetate copolymer (EVA) encapsulant, EVA is a copolymer of ethylene & vinyl acetate. The EVA contains 28–33 wt% of vinyl acetate (VA) for PV module encapsulation, and polyethylene (PE) is the remaining part. The lamination process of perovskite solar cells is more or less similar to the lamination process of c-Si solar cells glass to glass lamination but here cells can’t be soldered because of the thermal sensitivity of perovskite cell material. Conductive copper tape has been used to create the terminal of course it has its own disadvantages, the resistance of tape will decrease the PCE of the cell. Thermal sensitivity of a perovskite solar cell makes it complex to do lamination process to check the effect of laminating temperature we have measured the change in the absorbance before and after lamination by using UV vis spectrometer (make: Jasco, model: V-650 Series). Absorbance of cells is shown below and the Tauc plot of absorbance shows that the band gap of the cell before and after lamination is almost the same. From this we can expect that the lamination temperature of 90ºC will show no deleterious effect on the performance of perovskite solar cells. This work was done by PhD student Maruthi Avula under the guidance of Prof. Sudhanshu Mallick.

(Top) Cell before (a) and after (b) lamination; schematic structure (c). (Bottom) Tauc plot of absorbance of cell 1, before and after lamination.