Backsheet defects in field-deployed photovoltaic (PV) modules can reduce the availability of the plant due to inverter tripping and also cause potential harm to the personnel through electrical hazards. NCPRE, through its field studies, has shown that the backsheet defects can be latent and are likely to be missed by variants of dry/wet insulation resistance tests if they are applied to field- deployed modules. Also, these latent defects can be difficult to detect visually, can show seasonality, and also pose a challenge in identifying safe modules for potential reuse applications. A new characterization test is developed that can accurately identify the latent insulation defects in field- deployed modules that currently cannot be reliably captured by any of the available tests in PV module qualification/ safety standards. Detailed Finite Element Method (FEM) simulations are performed to explain the fundamental principles for the new test, and results of applying it on good as well as defective modules are in the paper “Development of a characterization technique to effectively detect latent insulation defects in the field-deployed PV modules”, by E.R. Anagha, S.V. Kulkarni, Narendra Shiradkar to be published in Solar Energy Materials and Solar Cells, Vol. 292, pp.113761 (2025), doi.org/10.1016/j.solmat.2025.113761. This test leverages the fact that water vapor exposes the insulation defects by resulting in accelerated ingress into the module packaging and reducing the insulation resistance. It is shown that the new test is significantly more effective than a variant of the typically used dry insulation resistance test in identifying latent insulation defects. The test is developed in such a way that it provides a reasonably high throughput and has the potential to become a benchmark test for detecting latent defects in the insulation of field-deployed PV modules. This work was performed by NCPRE PhD student Anagha ER, working with Prof. S.V. Kulkarni and Prof. N.S. Shiradkar.

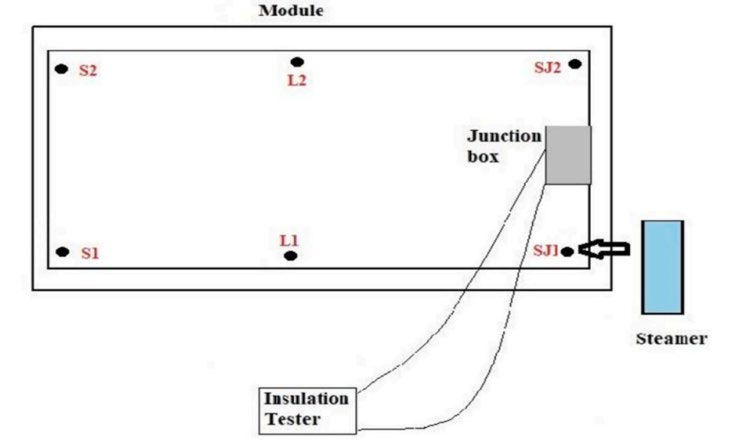

The new characterization test involves applying high voltage, similar to that in dry insulation resistance test, across the module terminals and recording the insulation resistance after a minute of steam exposure. If the module has insulation defects, the insulation resistance rapidly drops below the threshold specified by IEC 61215.