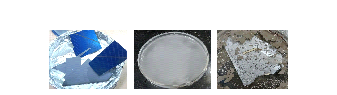

Recycling photovoltaic (PV) panels using chemical techniques is an essential part of managing end-of-life solar panels, particularly as the industry matures and more panels reach their end of life. NCPRE has been working on this important aspect for the last few years. The recycling process aims to recover valuable materials while minimizing environmental impact. The chemical recycling process for PV panels typically involves delamination, material recovery and purification. In Delamination, chemicals such as toluene or other solvents can be applied to dissolve or weaken the adhesive bonds between layers, allowing for easier separation. For Material Recovery, the silicon wafers can undergo purification processes using chemicals to remove impurities and recover high-purity silicon suitable for reuse in new solar cells. Metals such as silver and copper can be extracted through hydrometallurgical methods, where solutions containing acids or other reagents dissolve these metals for recovery. Solvent treatment was given to Silicon solar cell, the silver tabbed wafer cell used as sample here was acquired from the NCPRE fab lab. The sample was immersed in a series of acidic solutions for removal of the Al from the backside and Ag contact grid from the front side of the cells. In the figure, the leaching of metal is visible. The sample was dried under ambient conditions and further inspections were carried out via SEM and other analytic techniques to explore impacts at microscopic level. This work was carried out by NCPRE student Ms. Nivedita S. Iyer working under the supervision of Prof. Sudhanshu Mallick.

(Left to Right): Si wafer cell; Al removal; leached Al.