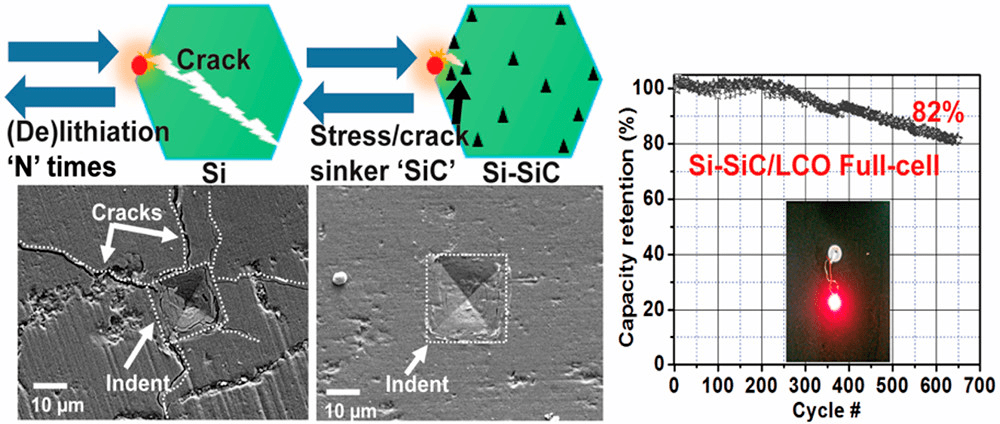

Silicon (Si)-based materials are one of the anode materials for next-generation lithium-ion batteries with high theoretical capacity and low working potential. However, extreme volume changes and mechanical instabilities in these anodes are responsible for premature failure in lithium-ion batteries. Thus, it is a crucial hurdle towards developing high-performance Si-based batteries, especially in the current scenario of electric vehicles. To improve the mechanical properties of Si-based anodes, various strategies have been explored. Here, the energy storage group demonstrated a significant improvement in the mechanical stainability of Si-based anode material via in-situ incorporations of carbide with a specific design, thereby bestowing outstanding stability in the electrochemical performance. A bridge between nanomechanical and electrochemical properties, investigated via advanced in-situ measurements during electrochemical cycling for Si and in-situ reinforced Si–SiC (Silicon-Carbon) composite, is established. Enhancing the hardness (H) of Si–SiC composite to almost twice and enhancing the hardness to effective Young’s modulus ratio of the same to almost thrice than that of Si, helped resist the occurrence of plastic deformation and cracking in compelling terms.

By contrast, monotonous stress profiles and the absence of the signature of plastic flow/cracking are observed for the Si–SiC electrode, which is an advantage for long cycle life, as observed here. Overall, the experimental study has established the nanomechanical to electrochemical tie-up leading to 82% capacity retention over 650 cycles in a Li-ion full-cell along with the Si–SiC composite anode and LCO cathode, as shown in the figure below. The “power cycle” of the Si–SiC composite anode, with a variation of current density from 0.5 to 6.0 A g-1, also reveals excellent stability up to 2500 cycles.

sagar.mitra@iitb.ac.in