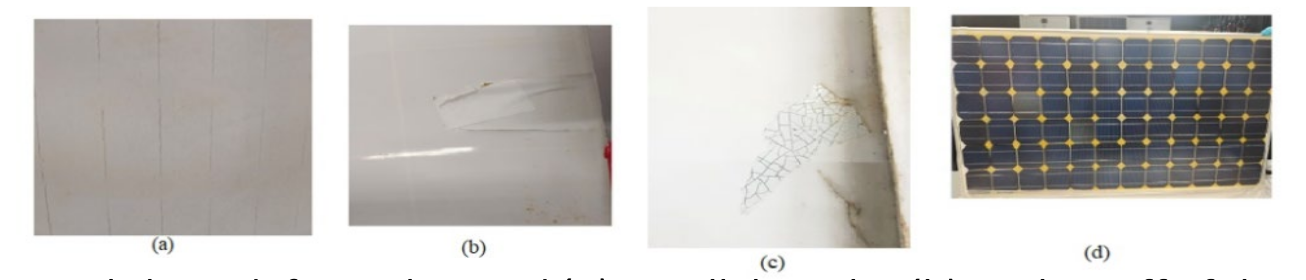

Very few laboratories in the world have the capability and know-how to accurately measure the resistivity of highly resistive materials such as PV backsheet or encapsulants. Even fewer labs would have the capability to measure this resistivity as a function of ambient temperature and relative humidity. NCPRE has established this facility and has successfully characterized fresh as well as degraded backsheet samples using this technique. NCPRE obtained various modules from the field that had developed backsheet defects from an industry partner. The various defects considered in this study are shown below, and the Table shows the outer layer materials for these backsheet samples and the dry insulation resistance value measured in the lab. It can be seen that all samples passed the dry insulation resistance test.

Backsheet defects observed (a) parallel cracks, (b) peeling off of the outer layer, (c) cracking of the inner layer, and (d) yellowing of backsheet

Backsheet condition |

Outer layer polymer |

Dry insulation resistance (MΩ) |

|---|---|---|

| Fresh | Polyvinylidene fluoride (PVDF) | - |

| Parallel cracks in the outer layer | Polyamide (PA) | 596 |

| Large cracks in the inner layer | Fluoroethylene vinyl ether (FEVE) | 617 |

| Yellowing of core layer | Polyamide (PA) | 359 |

| Fine cracks in the inner layer | Unidentified | 2100 |

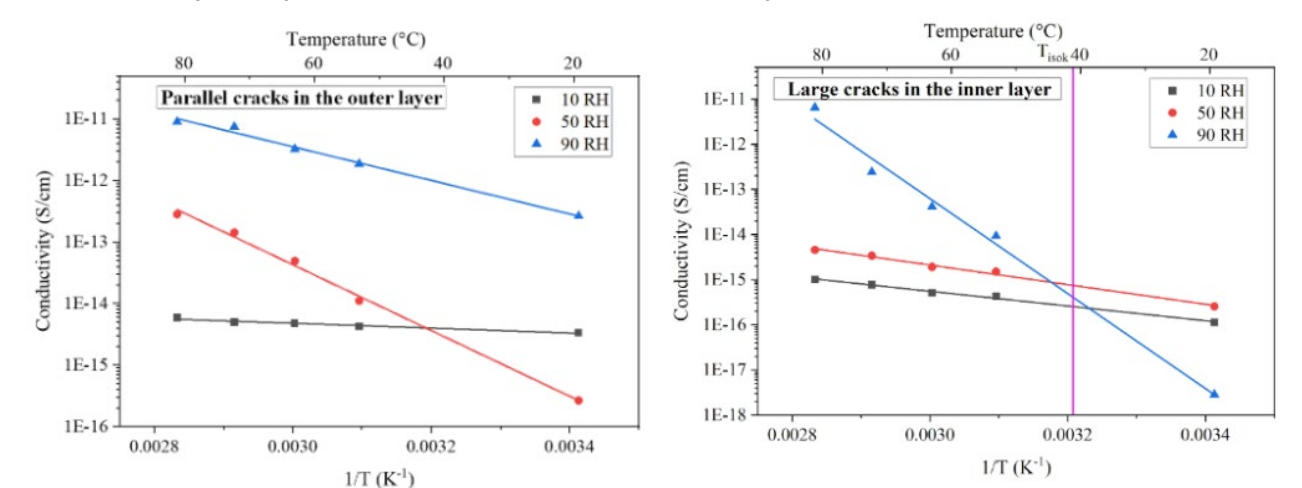

Temperature and Relative Humidity dependent conductivity of backsheet samples with defects. It can be seen that for these defects, conductivity increases by orders of magnitude at higher relative humidity values and can lead to inadequate dry insulation resistance in the field, leading to inverter tripping.

Inadequate dry insulation resistance in the field can result in inverter tripping, thus reducing the energy output from the PV plant down to zero. Backsheet samples were extracted from these fielded modules for detailed characterization. When temperature and relative humidity dependent conductivity characterization was performed for these backsheet samples, it was found that for backsheets with large cracks in outer or inner layers, the conductivity can increase by almost two to three orders of magnitude as shown below. Such cracks can significantly increase the moisture ingress into the module leading to conductivity increase at the backsheet as well as encapsulant level. Thus, in the worst case, during monsoon months when the ambient relative humidity is consistently high, considerable moisture ingress into the module packaging can happen, leading to inadequate dry insulation resistance offered by the PV strings to the inverter. Hence, modules with such backsheet defects are at higher chance of causing inverter tripping in the field than other cosmetic defects such as yellowing / chalking of the backsheets. This work was recently presented at the 41st EUPVSEC Conference in Vienna in September 2024: Anagha ER, SV Kulkarni and Narendra Shiradkar, “Electrical characterization of fresh and degraded photovoltaic backsheets based on temperature and humidity-dependent dc conductivity.”