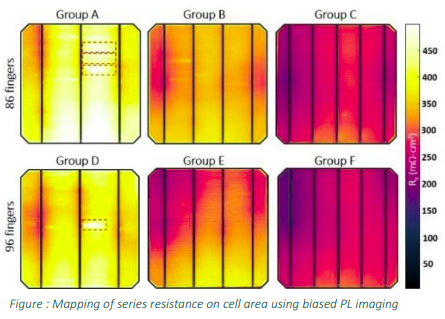

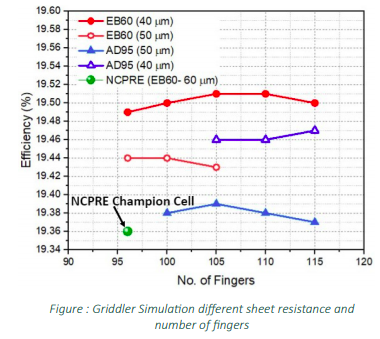

There is a continuous effort in optimizing the crystalline silicon (c-Si) photovoltaic (PV) manufacturing, which includes Si growth, wafer cuting, cell fabrication, and module production to increase the ultimate PV module power conversion efficiency along with the cost reduction. Considering the cost aspect, particularly in cell processing, silver (Ag) used for front metallization remains as the most expensive non-Si material. Nearly 100 mg of Ag per standard 6”x 6” Si solar cell is used and this has to be reduced down to 50 mg by 2029, as proposed by ITRPV 2020. Overall, it is essential to continue the efforts to lower the Ag consumption for further cost reduction. However, it is equally vital to optimize Ag consumption precisely, as it plays a crucial role in the power conversion efficiency of a solar cell. At NCPRE, we have developed a comprehensive methodology involving PL imaging and Suns-Voc measurement in the selection of front grid design for n+ diffused emitier silicon wafer solar cell. PL imaging under different bias condition provided a detailed understanding of the spatial distribution of recombination and resistive losses. This information can be then utilized in simulation packages like Griddler to optimize the Ag front contact design. Solar cell manufacturers are welcome to collaborate NCPRE to take advantage of this combination of characterization and predictive modelling for their process optimization.