According to the ITRPV (Eleventh Edition, April 2020) roadmap, Passivated Emitier Rear Contact (PERC) cell technology is expected to gain a market share > 70% in 2020 with Aluminium Back Surface Field (Al-BSF) cells technology trailing far behind at 20%. In September 2019, Canadian solar, one of the world’s largest solar cell manufacturing company set a world record of 22.80% conversion efficiency for p-type large area (246.7 cm2 ) multi-crystalline PERC solar cell.

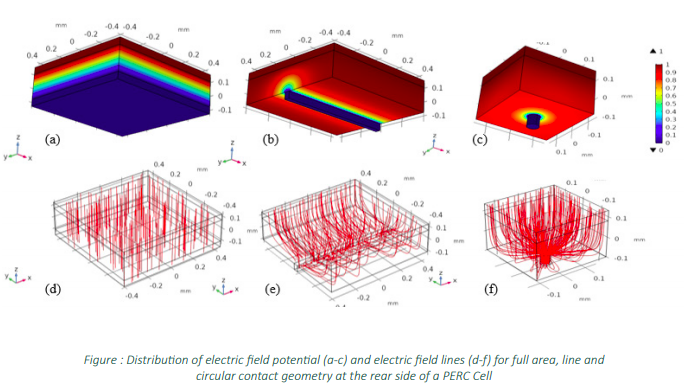

Development of high efficiency PERC Cells is one of the most important activities of the silicon solar cell group of NCPRE. PERC technology uses a combination of dielectric surface passivation and reduced metal/semiconductor contact area to decrease the rear surface recombination. The reduced metal contact scheme increases the effective internal surface reflection at the rear side as an Al/Si interface reflects only 65% of the incident light compared to > 90% in case of dielectric/Si interface. But these advantages come at the cost of increased series resistance due to additional spreading resistance as a result of reduced metal contact area. Investigations indicate that the pitch and the size of the rear point contacts which define the metallization fraction along with the substrate resistivity are fundamental design parameters for PERC cells. figure below (a-c) shows the potential distribution simulated in COMSOL Multiphysics for three different contact geometries namely full area, line and circular contacts. The electric field lines shown in figure below (d-f) due to partial rear contact are crowded leading to the additional spreading resistance.