Perovskite Solar Cell (PSC) technology has shown remarkable improvement in efficiency, increasing from 3.8% in 2009 to its present-day level > 25%. However, short lifetime and vacuum processed deposition of gold/silver counter electrodes are the significant obstacles for their commercialization, limiting this technology to lab-scale fabrication. Carbon, with the −5 eV work function comparable to gold and its properties like superior electrical conductivity, chemical stability and low-cost in particular, make it an appropriate choice as the alternative and economical perovskite counter electrode. Above all, the facile printability of carbon paste on the various substrates provides the opportunity for large area and roll-to-roll fabrication of PSC. We have prepared highly conductive (sheet resistance 8.43 Ω □ −1 ) and hydrophobic (contact angle 148.5°) perovskite compatible low-temperature curable carbon paste. The perovskite solar cell without an expensive organic hole collection layer fabricated with the carbon layer. The prepared device with 11.43% efficiency has shown remarkable ambient stability, retaining more than 53% of their initial efficiency after one month.

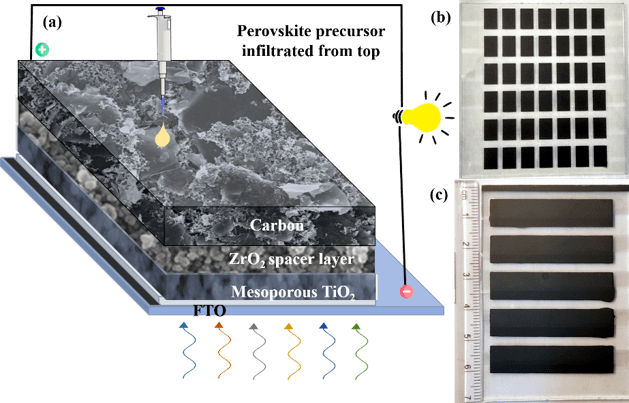

Large area screen printed carbon-based perovskite solar cells and mini-modules were also prepared. Single-cell with an active area of 2 cm 2 has an efficiency of 6.20%. The cell with the same configuration having the small active area of 0.13 cm 2 shows 13.36% efficiency. Perovskite mini-modules were fabricated by connecting cells in the series. 4 cm 2 mini-module with two 2 cm 2 active area cells connected in the series gives 4.81% efficiency. We have also fabricated the five-cell mini-module with a 10 cm 2 active area (5 cells of 2 cm 2 active area connected in series) as shown in the figure. These mini- modules show the Voc of 4.1 V. All the devices show significant stability under continuous illumination. These results are encouraging and can contribute towards the realization of low-cost, large-scale, and stable perovskite solar cells, which will be a positive leap towards its mass production and make this technology commercially viable.

mallick@iitb.ac.in