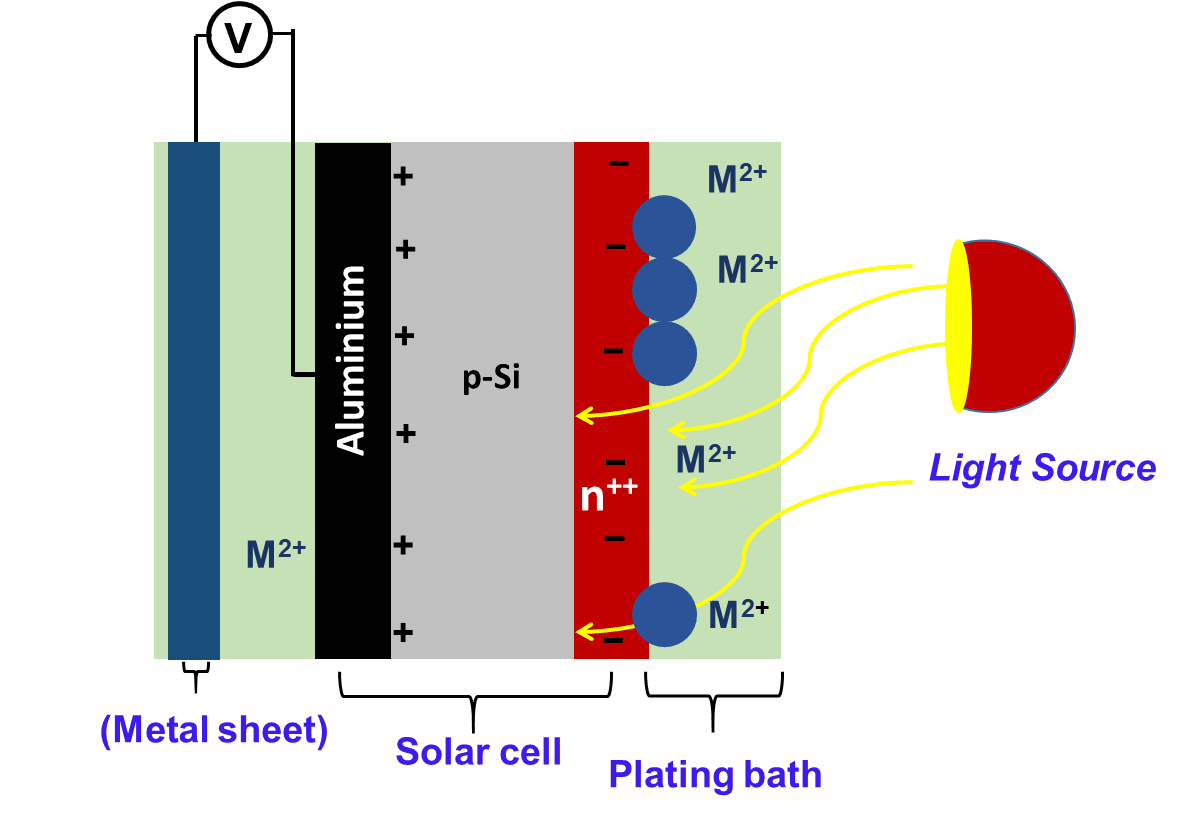

Conventionally, silver (Ag) screen-printed (SP) front side contacts are used in Si-based solar cells. Such contacts with costly Ag cause efficiency losses in the cells due to shading, poor line conductivity and contact resistance. A promising alternative contact is based on cheap and readily available Cu, which forms a good contact comparable to Silver (Ag). However, large scale implementation in the industry remains elusive due to its reliability concerns. Statistics show that by 2029, only 10% of the total cells produced will be those with Cu contact. The significant drawback of Cu is that it causes junction breakdown by diffusing into the Si layer. To prevent the diffusion of Cu in Si, Ni can be used as an effective barrier layer. At NCPRE, a team of researchers has adopted light-induced plating (LIP) developed by Fraunhofer ISE for the metallization of the silicon solar cell. LIP utilizes the photovoltaic effect, and it is attractive from the perspective of overcoming background plating. Further studies are being conducted to study its feasibility in a commercial environment further.