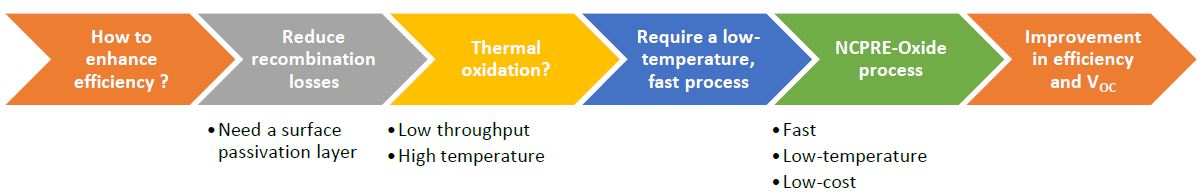

The evolution of Silicon (Si) solar cell technology, from

aluminium-back surface field structure to A1-BSF

high-performance interdigitated back contact (IBC) and

Tunnel oxide passivated contact (TOPCon) structure, is

possible because of advances in surface passivation

techniques. A passivation layer can reduce the surface

recombination losses by minimizing the surface states

density by saturating the dangling bonds and by

introducing a surface field.

In silicon solar cells, different schemes are used to

passivate the surfaces such as silicon dioxide (SiO2),

hydrogenated amorphous silicon nitride (SiNy:H),

hydrogenated amorphous silicon, high-low junctions.

The thermally grown SiO2

is an excellent surface passivation layer. However,

thermal oxidation at high temperature (~1000°C) can

cause severe bulk lifetime

degradation, especially in multi-crystalline silicon wafers.

The thermally grown oxide has limited industrial

applicability due to low throughput and high cost.

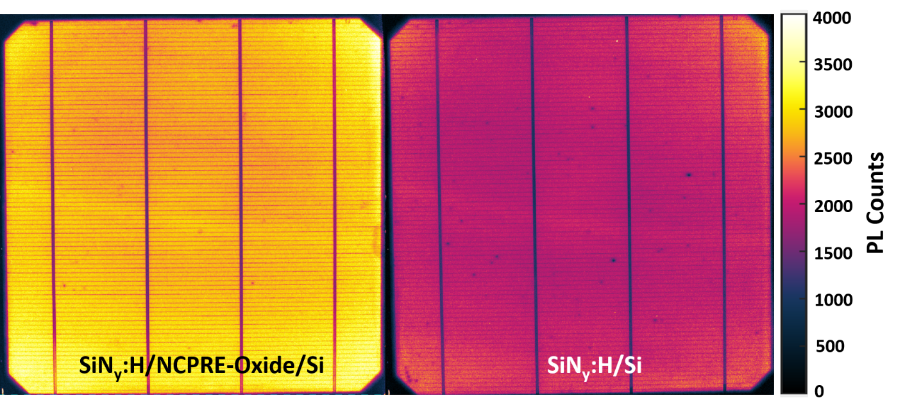

Silicon-Oxide (SiO) process, in contrast, is a fast

(< 5 minutes), low-temperature (< 40°C) and low-cost process.