Encapsulant is an important component of solar module which provides strong adhesion

between solar

cells and top surface (glass) and rare surface (backsheet). Ethylene-Vinyl-Acetate

(EVA) are most

commonly used encapsulate.

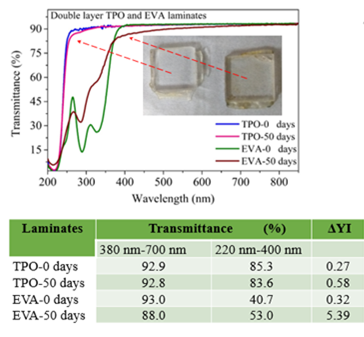

Thermoplastic Polyolefin (TPO) is a newly developed non-crosslinking material for

photovoltaic (PV)

module lamination as an alternative to the ethylene-vinyl-acetate (EVA) crosslinking

encapsulant. We

report the results of various characterization tests for discoloration and optical

properties degradation

conducted before and atier the UV accelerated test. To evaluate its weathering

stability, the UV-365

acceleration test has been conducted on the glass to glass TPO laminate, with EVA as

a benchmark. In 50

days of weather ability tests, the transmittance of EVA significantly reduced while

TPO remained almost

unchanged. The Yellowness Index (YI) of TPO is around nine times slower than that of

EVA. Fluorescence

imaging of EVA shows yellow-brown colour due to the fluorophores generation. Also

fluorescence

emission is around nine to ten times higher for EVA when compared with TPO

encapsulant.

Raman spectra confirmed that the EVA-50 day's sample showed a strong fluorescence background due to the alpha-beta carbonyl fluorophores formation, whereas in TPO, did not show any fluorescence background. This UV weather test results confirm that TPO is a superior encapsulant than EVA. The details of publication on the different thermal stability and tensile stress-strain can be found in Page 13. From all the results, it can be concluded that TPO material can be a potential candidate for the PV module encapsulation.