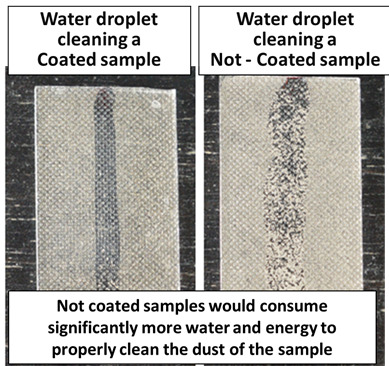

There is a high need for a cost-effective mitigation

strategy to reduce energy losses due to dust

deposition on PV modules. The most common

practice used for cleaning PV modules today is a

manual-water-based cleaning method, which also

to the global water crisis. Anti-soiling coatings (ASC)

is one of the most cost-effective universal solutions

to mitigate dust. It is applied on the top surface of

the PV module to mitigate dust deposition.

As these coatings are applied on the outer surface

of the PV module, durability of these coatings

become an essential factor. Among the many

commercial anti-soiling coatings available in the

market, we had tested 4 commercial hydrophobic

anti-soiling coatings (catered to PV application)

under outdoor field exposure in warm and humid

climatic condition.

We saw that all coatings degraded in 3 months.

We further identified the stressors which degraded

anti-soiling coatings under field conditions.

The factors that degraded the ASC are listed below :

Rainfall- Frequent cleaning (manual or natural cleaning by rain)

abrades the ASC, which was identified as a statistically significant

stressor in both outdoor field exposure test and indoor individual

stress tests. The effect of frequent cleaning on the field was more

severe, as, in the real field condition, combination of

stressors acted concurrently.

Acid rain- Signatures of acid rain were seen in outdoor field

test samples. The laboratory acid rain/acid immersion test showed

that hydrophobic coated samples became hydrophilic in 220 min of acid

immersion.

Combination of UV exposure and condensation- We saw that the effect of the

combination of UV

exposure and condensation shows a higher rate of degradation than the individual

stress test of only UV

exposure and water immersion. This indicates that combination of stressors, also

seen in field

exposure, degrades the coatings at significantly higher rates than individual

accelerated stress test.

Understanding the factors that degrade ASC on field, can be used in developing a

standard test sequence,

which will act as a baseline for the present commercial antitisoiling coating market

and will also help in the

development of durable antitisoiling coatings. For more detailed information, please

refer to the paper -

Sonali Bhaduri, Ajeesh Alath, Sudhanshu Mallick, Narendra S Shiradkar and Anil

Kottantharayil.