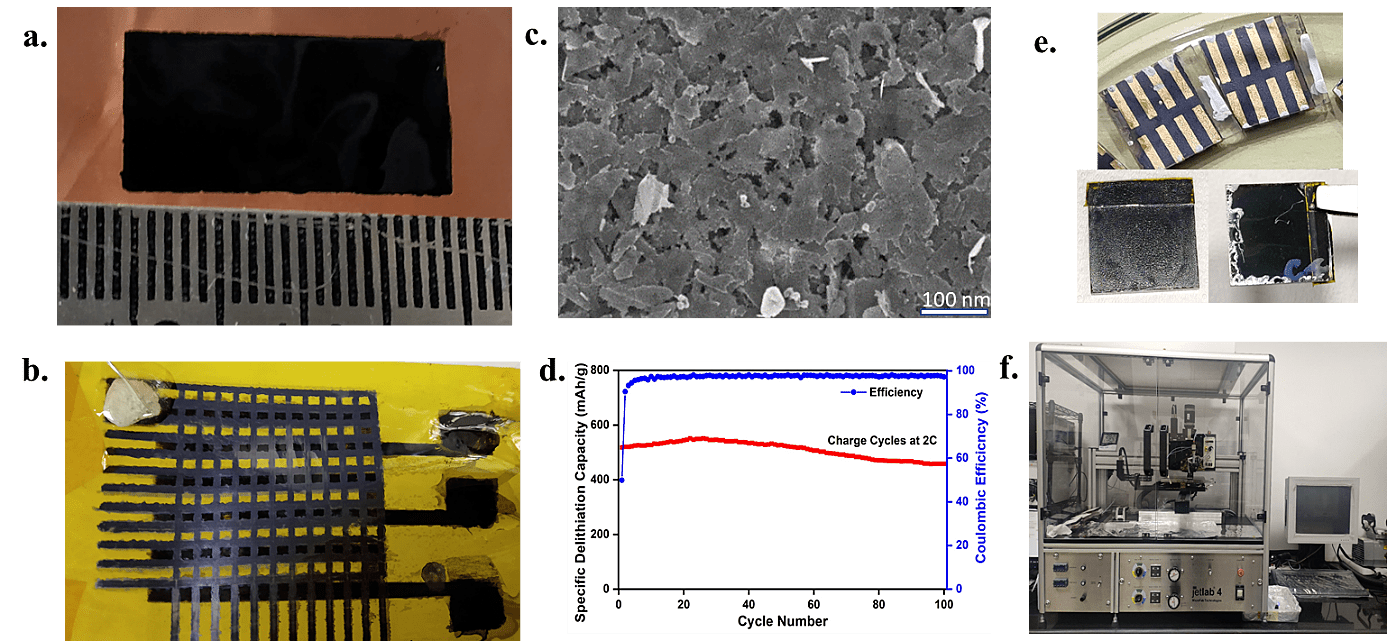

Inkjet printing is a versatile fabrication technique that can fabricate electronic

devices in a digital non-

contact mode that allows for printing on large areas and a variety of substrates

with low wastage of

materials, rendering it cost-effective, facile and scalable. Our group has developed

inkjet printed micro

porous thin film graphene electrode for high-performance lithium-ion battery, where

printed electrode

can retain 87% of initial reversible capacity after 100 cycles at high current

density and reversible capacity

of 942 mAh/g at 0.1C low current density. In this context, a thin-film Li-ion

battery (LIB) system is being

considered as a more suitable power supply since it has favorable features, such as

being flexible, light

weight, and thin, together with unparalleled high energy and power densities. More

importantly, the

reduced thickness of the electrodes helps with faster kinetics, leading to enhanced

rate capability.

However, fabrication of thin-film electrodes for LIBs is challenging and mostly

relies on traditional thin-

film deposition techniques, such as chemical vapor deposition (CVD), sputtering and

pulsed laser

deposition (PLD), and Sol–gel methods such as Dip/tape Casting and the Doctor Blade

technique.

Unfortunately, many of these methods require expensive and sophisticated

equipment(s), with

necessities concerning attainment of a high vacuum and high temperature, which limit

the development

of thin-film batteries.

Perovskite solar cells (PSCs) rose to their current fame due to their rapid performance growth in a short period of one decade, as compared to silicon solar cells. Though they have achieved high performance using lab-scale techniques, their stability and scalability still remain a roadblock towards commercialization. Inkjet printing, an efficient and scalable method, can be applied to fabricate different functional layers of perovskite solar cells. As a benchmark for comparing inkjet-printed perovskite solar cells, the primary step was to develop PSCs using spin-coating techniques. We have achieved 14% and 8.35% efficiency with triple cation perovskite in n-i-p mesoscopic and planar architectures in nitrogen atmosphere, respectively. The inkjet-printed PSCs with triple cation perovskite fabricated in ambient condition with humidity greater than 80% reached efficiencies of 2.4% and 1.24% in n-i-p mesoscopic and planar architectures, respectively; which is under further optimization with respect to various parameters pertaining to inkjet printing.