For decades, Si has dominated the semiconductor market due to its abundance and low cost. Almost every circuit has some Si based component. Power Electronic circuits are no exception. To this date, most converters use Si transistors as switches. More than 60% of the space on a converter circuit board is occupied by bulk capacitors and magnetic components. Because these components transfer energy every second, their size depends on the operating frequency. Si fails to provide considerable size reduction in high power circuits because it struggles to operate efficiently at high frequencies (>100kHz). Hence, Si-based high-power solutions tend to be bulky. This is where GaN steps in

GaN enables efficient operation at high frequencies (>100kHz) which means that the

size of magnetic

components can be decreased allowing for power efficient high-power density

circuits. GaN based

converters are more compact, dissipate lesser heat and pack more power per unit

volume than their

Si-counterparts. The BLDC driver under development at IIT-B uses GaN transistors to

operate at higher

frequency because at high frequencies, the current ripple and hence the amount of

DC-Link capacitance

required decreases. This means that smaller film capacitors can be used instead of

bulky electrolytic

capacitors. With GaN transistors, the team was able to increase the operating

frequency to 4x that of initial

prototype and get 50% theoretical reduction in C-Link capacitance and 40% lesser

losses per switch.

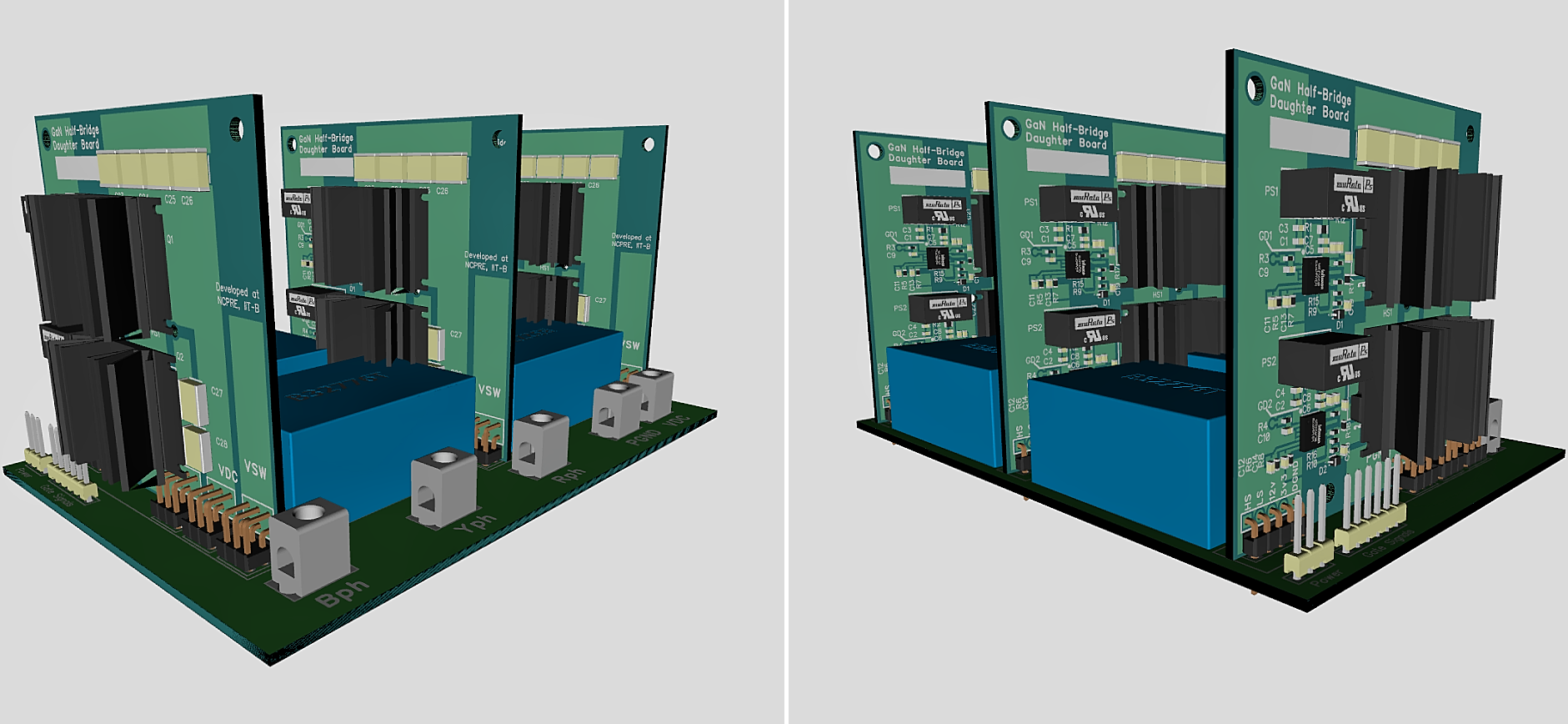

Owing to higher operating frequency, lesser losses and easier thermal management,

the team was able to

decrease the power stage size to 1/3rd that of the Si-based prototype. This allowed

them to design

modular half bridge cards (daughter boards). 3 such daughter boards when plugged

into a motherboard

(which carries DC-Link capacitors) complete the power stage of the BLDC driver. This

plug-n-play features

makes the motor driver highly modular. In case of a failure in any of the phases,

the corresponding

daughter board can be simply pulled out and replaced like a Lego block. This

modularity facilitates easy

debugging, quicker maintenance and shorter downtime.

| Criteria | Si | GaN | Reason |

|---|---|---|---|

| Operating Temp | Lower | Higher | GaN has higher Bandgap than Si |

| Operating Temp | Lower | Higher | GaN device has lower CISS, COSS meaning faster turn-on, turn-off and lower switching losses |

| Device Size | Bigger | Smaller | GaN has higher critical elec. field, which means for same breakdown voltage, GaN device can be much smaller (VBR = 0.5*wdriti*Ecrit) |

| RDS-ON | Lower | Higher | Higher electron density and much smaller drift region in GaN |

| Device Parasitic | Lower | Higher | Instead of Au bond wires, modern GaN devices have a “laminated structure” interconnected with thick Cu-filled vias for terminal connections |

| Cost | Lower | Higher | Fabrication Complexity |