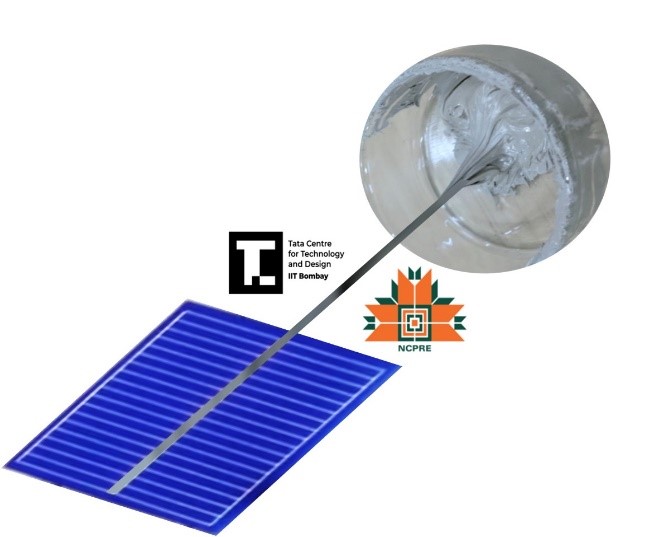

With the rapidly increasing solar PV installations in the country, it is expected that within the next several years, solar PV will become a significant contributor to India’s power requirements. Atmanirbhar Bharat Abhiyan is providing a significant push to developing raw materials and components within the country. In line with the Abhiyan, we have been working towards the development of PV grade silver paste used in the manufacturing of silicon solar cells. At the present solar cell production output, India imports around 50 tons/year of silver paste worth around INR 500 – 700 Crores per year.

Besides silver powder, the silver paste typically contains organic additives to make

it screen printable and a

customized glass powder in minor amounts which helps to etch the silicon nitride

anti-reflection coating

(ARC) during firing at elevated temperatures. The nature and amount of organic

additives have to be highly

customized to achieve a flow behaviour (rheology of paste) such that current

collection grid lines of fine

width can be printed on the ARC deposited silicon wafer. Etching the ARC layer, the

glass powder also plays

a crucial role in precipitating fine silver particles at the interface of the wafer

and paste to develop the

desired electrical contact.

Utilizing our experience in materials synthesis and designing of the flow behaviour

of slurries and pastes,

we initiated the work on the development of silver pastes. In the past 2-3 years, we

have developed our

silver powders, glass powder of suitable composition and formulated screen printable

pastes. The NCPRE

facilities were utilized to screen print as well as fire the wafers in both batch

and continuous furnace to

fabricate the solar cells. Till date, the best performing cells with our paste

yielded 15% photo-conversion

efficiency. Efforts are currently underway to establish the silver paste composition

for the presently most

popular industrial configuration of mono-crystalline p-type silicon wafers for

Al-BSF and PERC architecture.

Once pastes with superior repeatable performance are obtained, the knowledge would

be applied to

develop pastes for the emerging n-type silicon wafers solar cell technologies such

as the HJT TOPCon

followed by bifacial architectures also. We would be happy to receive any inputs

from the industry towards

the work being carried out on paste development and at a suitable time also seek

their assistance in the

evaluation of the pastes.